Common Challenges in Water Soluble Packaging and How Machines Address Them

Water soluble packaging has become an increasingly popular solution in industries such as detergents, cleaning products, pharmaceuticals, and healthcare. Its ability to dissolve completely in water offers convenience, precise dosing, and environmental sustainability. However, working with water soluble films introduces unique challenges in the manufacturing and packaging process. Specialized water soluble packaging machines have been developed to address these issues, ensuring consistent product quality and operational efficiency.

Sensitivity of Water Soluble Films

One of the primary challenges in water soluble packaging is the delicate nature of the films themselves. These films are highly sensitive to moisture, temperature, and physical stress. Exposure to humidity or water can cause premature dissolution, while excessive heat or pressure can lead to tearing or deformation. Such damage compromises package integrity and may result in product waste or contamination.

Manufacturers must carefully control the production environment to maintain optimal film performance. This includes regulating humidity, temperature, and airflow within the packaging area. Additionally, operators need to handle materials cautiously, as rough handling or improper storage can weaken the films.

Precise Dosing and Product Consistency

Accurate dosing is another critical challenge, especially in industries where single-dose packaging is standard. Whether packaging powders, liquids, gels, or granules, inconsistent fills can affect product performance and customer satisfaction. Manual packaging methods are prone to errors, as slight variations in weight or volume can occur with each unit.

Advanced water soluble packaging machines address this issue by providing precise, automated filling systems. In the middle of the production line, a high-quality Water Soluble Packaging Machine ensures that each unit receives the exact amount of product. These machines use volumetric pumps, auger fillers, or servo-controlled dosing systems to maintain uniformity across high-speed production runs, reducing waste and improving product reliability.

Maintaining Seal Integrity

The sealing process is one of the most critical steps in water soluble packaging. Improper sealing can lead to leaks, premature dissolution, or contamination. Water soluble films require precise temperature and pressure control to create a secure seal without damaging the delicate material. Variations in sealing conditions can result in inconsistent package quality and compromised product safety.

Modern water soluble packaging machines use advanced sealing technologies, including heat sealing and ultrasonic sealing, with fine-tuned temperature and pressure controls. Sensors and automated feedback systems monitor seal quality in real time, ensuring each package meets strict standards. This level of control minimizes errors and prevents material waste, while also maintaining compliance with safety and regulatory requirements.

Film Feeding and Handling Challenges

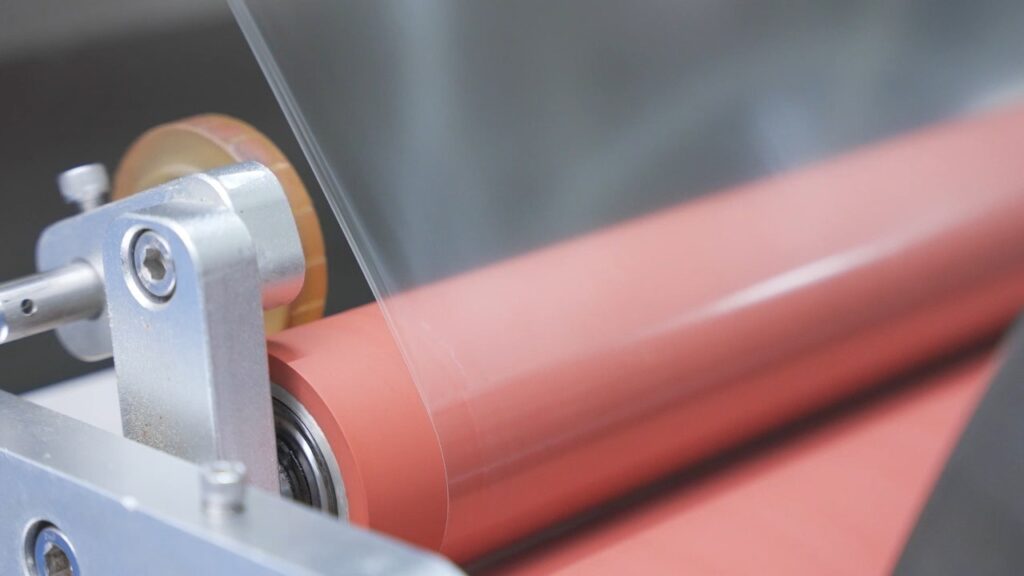

Proper film feeding is essential for uninterrupted production. Water soluble films are thin and prone to wrinkling, tearing, or misalignment if not handled correctly. Misfeeds can halt production, damage the film, and result in defective packages. Maintaining consistent tension and alignment is critical to prevent downtime and maintain efficiency.

Water soluble packaging machines are designed with precision rollers, tension controllers, and guiding systems that ensure smooth film feeding. These components protect the film from excessive stress and maintain proper alignment through forming, filling, and sealing operations. By automating these processes, manufacturers reduce manual intervention, lower error rates, and improve production efficiency.

Environmental and Storage Considerations

Environmental conditions can significantly affect water soluble packaging. High humidity, moisture in the air, or fluctuations in temperature can compromise both the film and the final package. Additionally, improper storage of raw film materials or finished packages can lead to sticking, premature dissolution, or package deformation.

To address this, modern packaging machines incorporate climate-controlled enclosures and humidity management systems. These features protect sensitive films during production, ensuring consistent quality. Proper storage solutions, combined with automated machine handling, further reduce the risk of environmental damage and minimize production interruptions.

Maintenance and Operational Reliability

Water soluble packaging machines, like any high-precision equipment, require regular maintenance to operate reliably. Accumulated residues, worn components, or misaligned parts can affect machine performance and package quality. Preventive maintenance, including cleaning, lubrication, and component checks, ensures smooth operation and reduces the likelihood of unplanned downtime.

Training operators to understand the specific requirements of water soluble films and the machine’s functions is equally important. Skilled personnel can detect early signs of issues and take corrective action, ensuring consistent production quality and operational efficiency.

Conclusion

Water soluble packaging offers numerous benefits, but it also presents unique challenges related to film sensitivity, precise dosing, sealing integrity, environmental control, and machine maintenance. Modern water soluble packaging machines are specifically engineered to address these challenges, providing precise, automated, and reliable solutions. By integrating advanced dosing systems, temperature-controlled sealing, tension-managed film feeding, and climate protection, these machines enable manufacturers to produce consistent, high-quality packages efficiently. Proper maintenance and operator training further enhance reliability, ensuring that water soluble packaging remains a safe, effective, and sustainable choice across multiple industries.